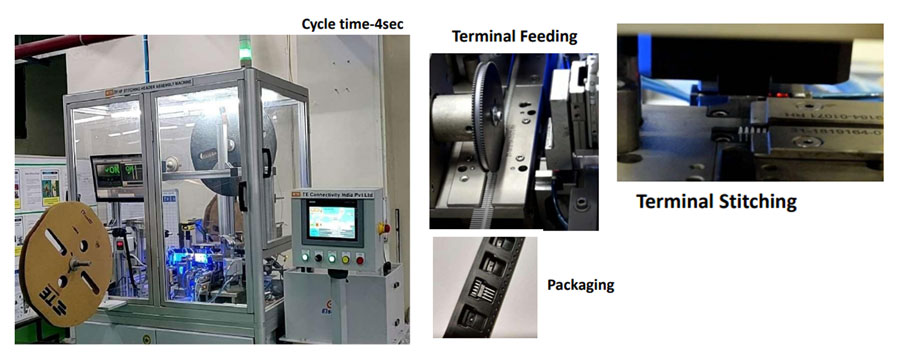

Assembly M/c :-2P/4P Terminal Stitching Header Machine

Stations Vacuum based Pick and Place System uses following process on part.

- Header & Terminal Feeding,

- Terminal Cutting,

- Pre-Insertion,

- Final Insertion

- Inspection,

- Packaging.

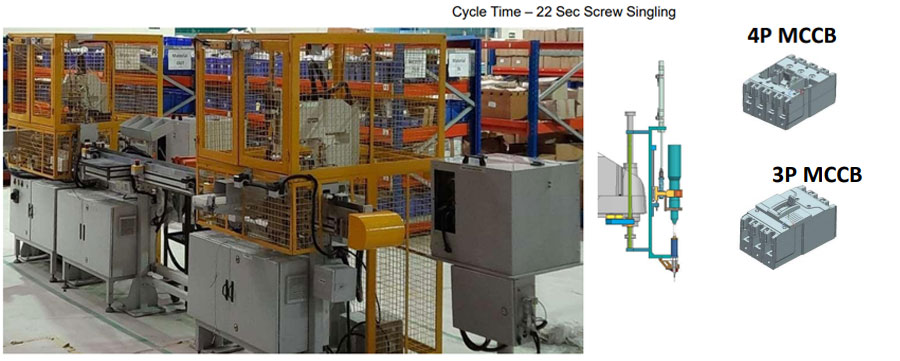

Fully automatic MCCB Feeding & Screw Fastening

Automatic Screw Feeding of Mid, Main Cover and Terminal Bolt with Servo based Pick and Place on Laser marking Station.

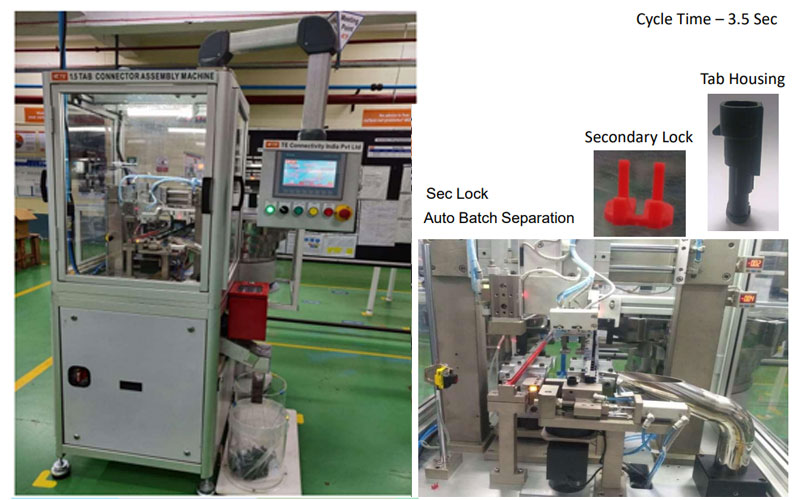

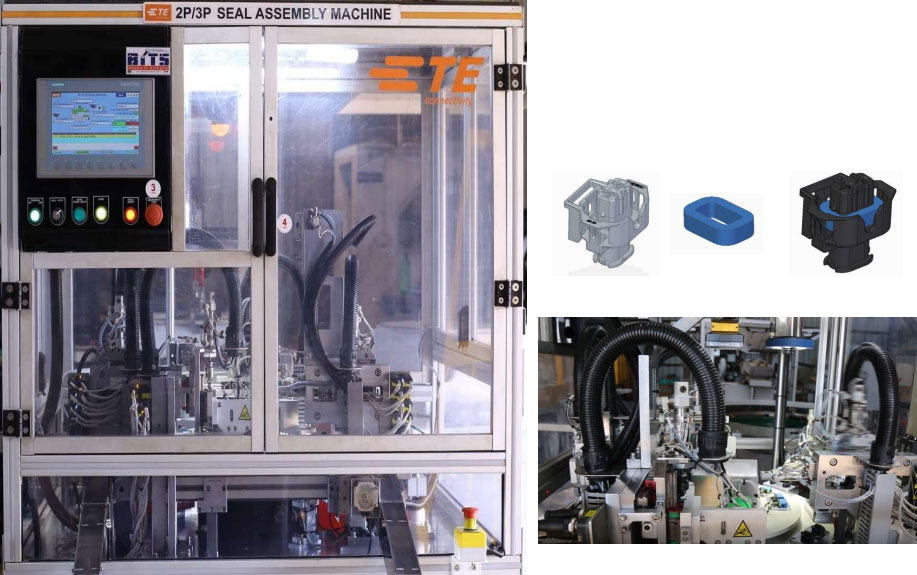

Tab Connector Assembly Machine

Automatic Feeding -Bowl Feeder

Check Point – Online Short filling Check and Height Check of

4 Child part Connector Assembly Machine

Automatic Feeding + Bowl Feeder

-Check Point --> Online Short --> filling Check and child part fitment check.

7 Child part Connector Assembly Machine

- Automatic Feeding -Bowl Feeder with 3000 capacity.

- Check Point – Model differentiation and every fitment Check.

- Auto Placing of FG Part in Tray with Matrix formation.

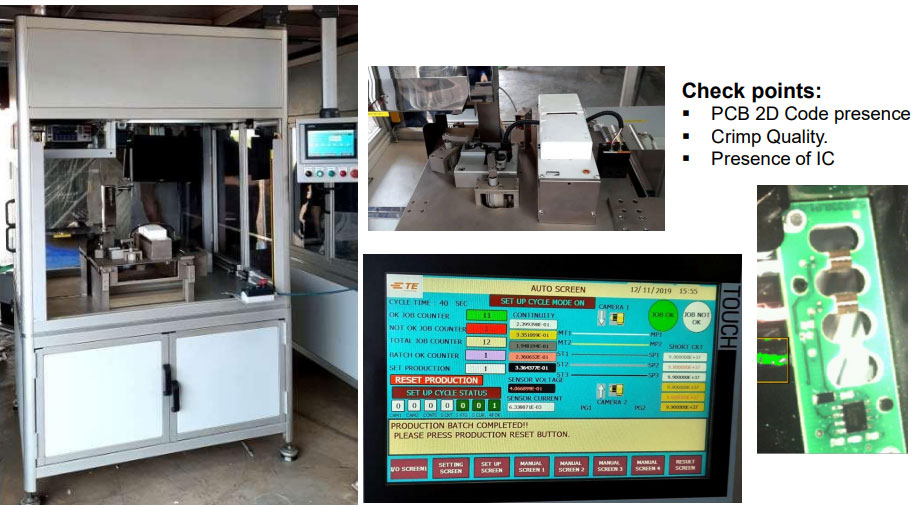

Oil Module PCB Checking and wire continuity checking Setup

Final Product Marking by Laser marking

Data Storage against each Marked part

Fully automatic 4 Child Part Assembly machine

Automatic Feeding - Bowl Feeder

- Check Point – Orientation and every fitment Check

- Auto Inspection and rejection

- Multi 12 Axis Servo Pick and Place

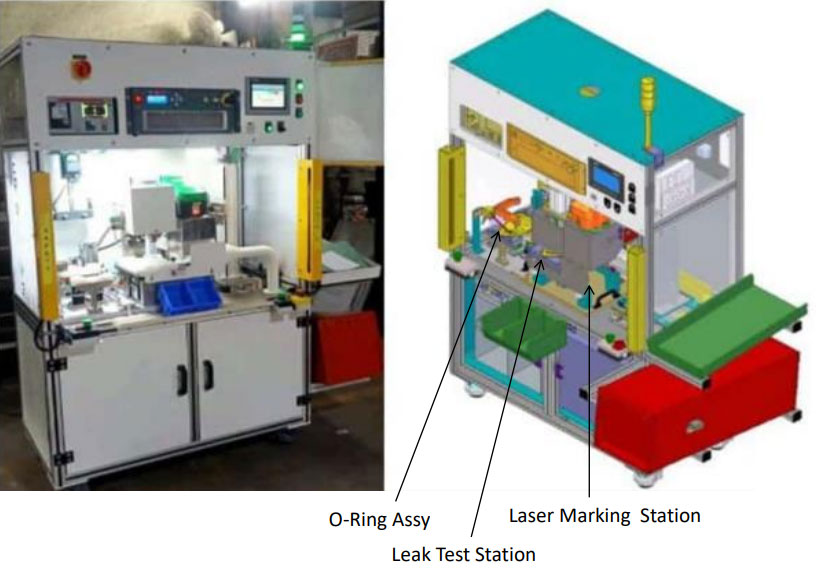

Automotive Filter Assembly : O-Ring Assembly --- Leak Testing --- Laser Marking SPM

2 Part Assembly machine auto Inspection & rejection

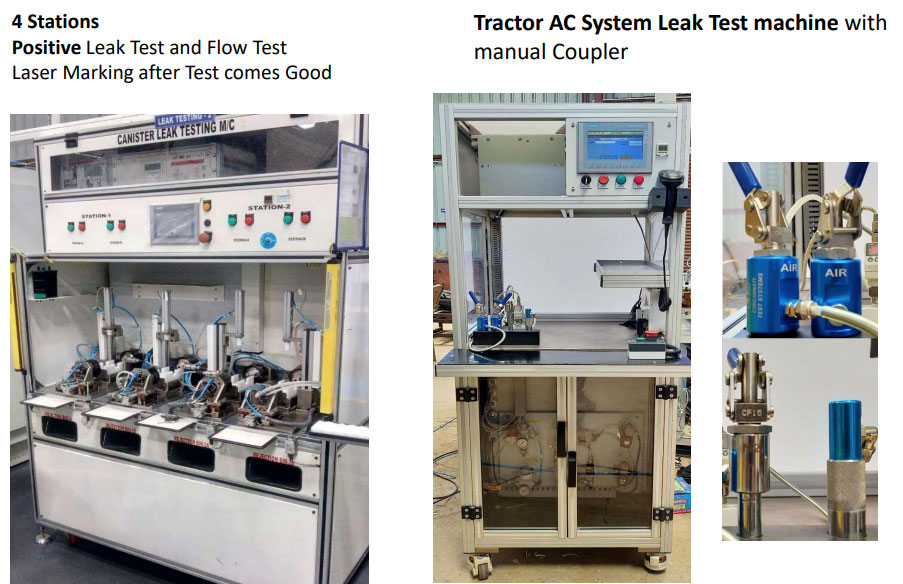

Leak Test Machine

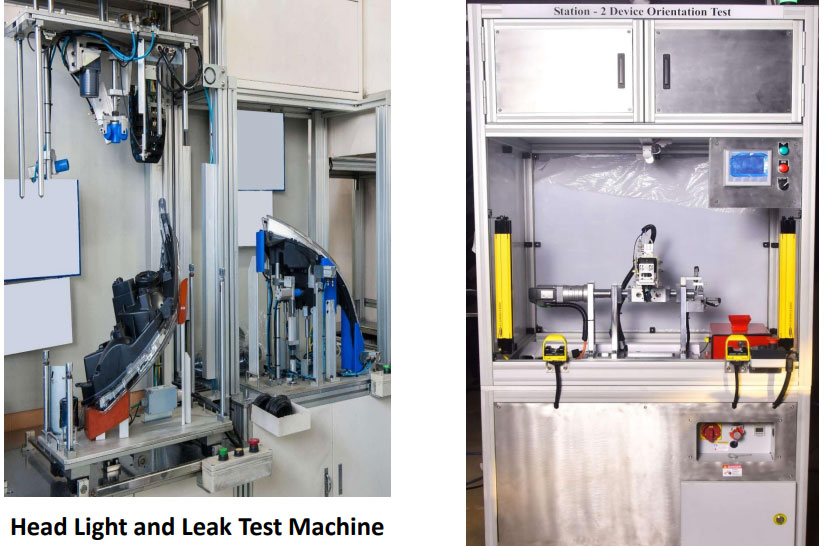

Pulsar , KTM Engine Filter & Casting Part Leak Test Machine

Leak Test Machine

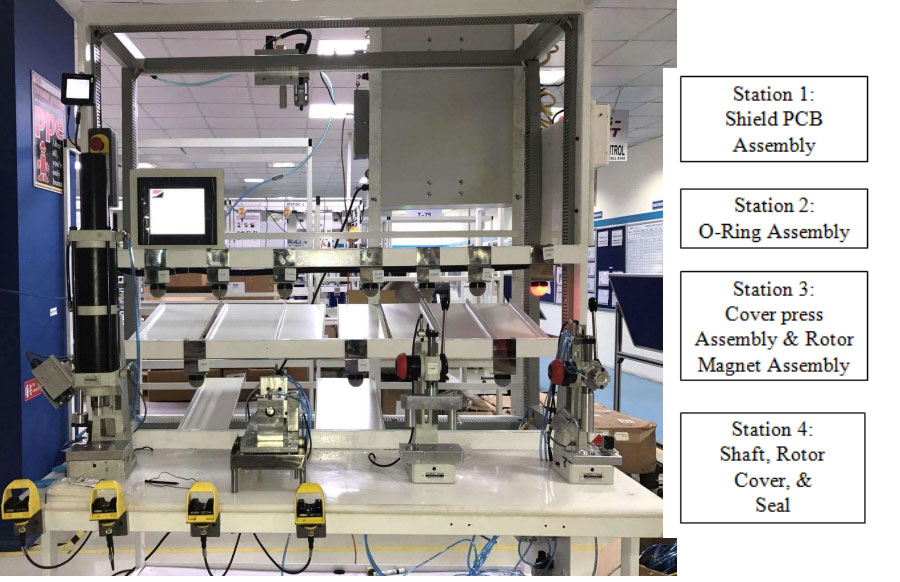

JCB Angle Sensor Assembly Line.

Material Handling & feeding System – Bowl Feeders, Hoppers, Conveyors and Elevator.