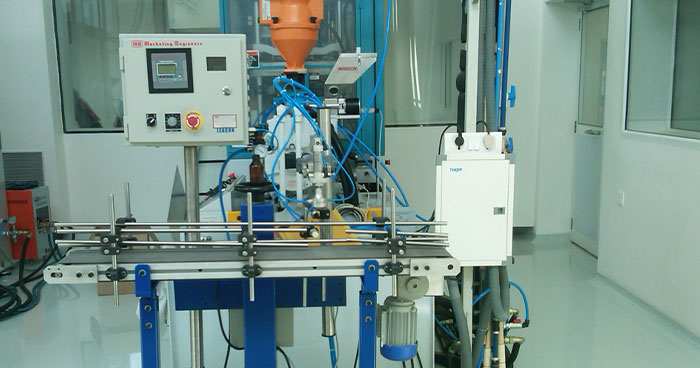

SPM – Leak Testing & Marking SPM

BITS Control and Solutions excels in providing specialized SPM (Special Purpose Machines) for Leak Testing and Marking, ensuring the highest levels of quality and reliability in manufacturing processes.

Our Leak Testing machines are designed to detect even the smallest leaks in critical components such as automotive parts, medical devices, and electronics, safeguarding product quality and ensuring compliance with industry standards. The Marking SPMs, on the other hand, integrate precision marking solutions that provide traceability and part identification for automotive, electrical, and consumer goods industries.

Applications:

- Leak detection in automotive fuel systems and brake components.

- Pressure testing for medical devices and electronics.

- Marking for traceability and product identification in manufacturing lines.

Key Features of Leak Testing SPM

- Precision Detection: Capable of identifying minute leaks that could compromise quality.

- Non-Destructive Testing: Preserves product integrity while ensuring quality control.

- Versatile Testing: Suitable for a wide range of applications across multiple industries.

Key Features of Marking SPM:

- Permanent Marking: Utilizes laser or inkjet technology for clear, durable markings.

- Customization: Tailored solutions to meet client-specific requirements.

- Seamlessly integrates with other assembly lines and testing processes.

Why Choose BITS?

- BITS’ Leak Testing and Marking SPMs ensure product reliability by detecting potential issues before they become problems, maintaining product integrity and enhancing quality assurance in your operations. These specialized machines streamline testing and marking